- Home

- Solution

- Metal Processing Services

- 5-Axis Machining

5-Axis Machining

Service Introduction

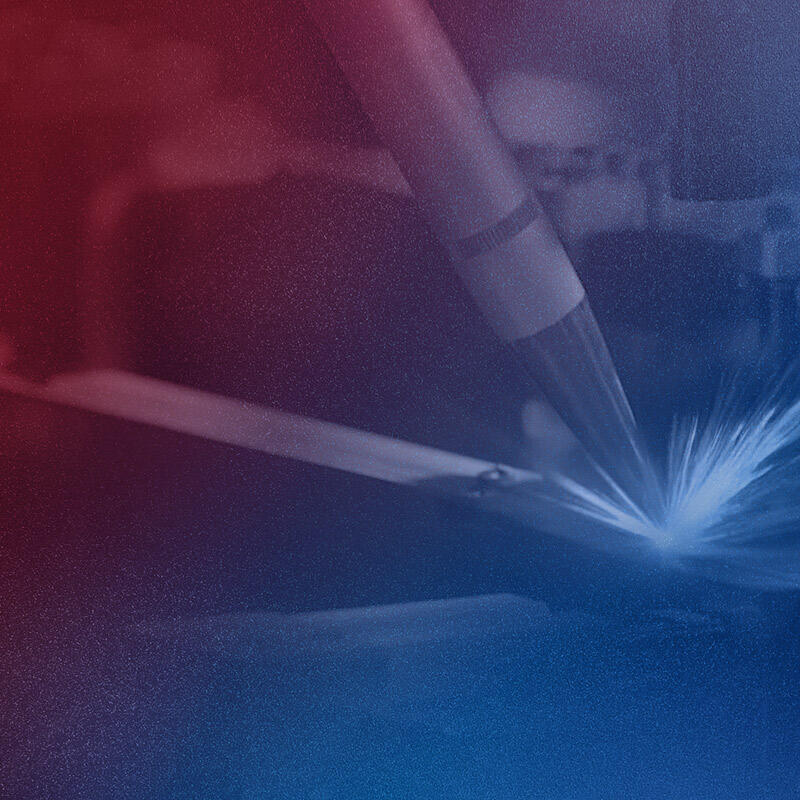

We offer high-precision five-axis machining services, capable of performing complex metal machining in multiple directions to achieve precise, detailed machining results. This service is suitable for the production of various precision components. Five-axis machining allows for processing workpieces from different angles, ensuring the accuracy of the part shapes, especially for those with complex contours and challenging machining requirements.

Five-axis machining provides high flexibility and precision, enabling the handling of complex shapes and intricate details. It improves machining efficiency and ensures high-quality finished products.

Compared to traditional three-axis machining, five-axis machining reduces the need for multiple workpiece clamping and minimizes motion errors, thus improving overall production efficiency and product consistency. Furthermore, five-axis machining is capable of meeting large-volume production demands and ensuring fast delivery times.

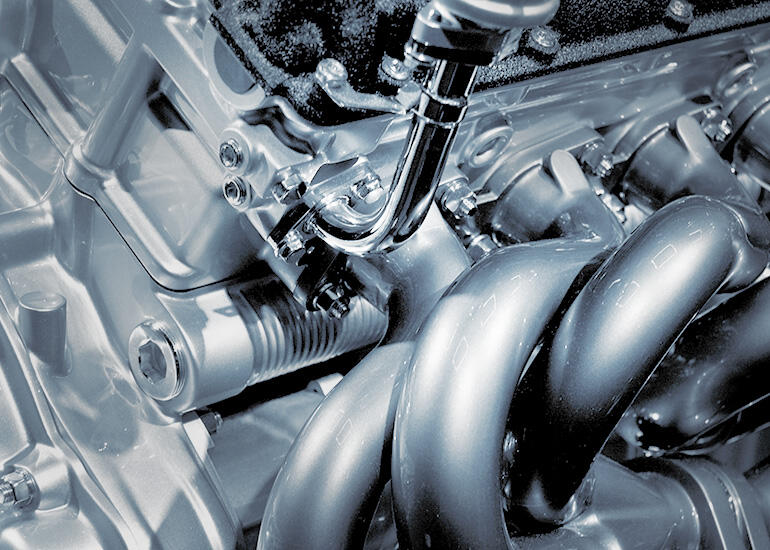

Five-axis machining is widely used in industries such as aerospace, automotive, tooling, electronics, and precision machinery, particularly for parts that require extremely high precision and complex shapes. In the aerospace industry, five-axis machining is extensively applied in the manufacturing of high-precision components such as aircraft engines, fuselage structures, and aerospace parts. Since these components must endure extreme working conditions and meet strict requirements for weight and strength, five-axis machining ensures the precise processing of these high-strength materials, guaranteeing the accuracy and quality of the parts while enhancing production efficiency.