- Home

- Solution

- Metal Processing Services

- Hydroforming, tube bending, pressing

Hydroforming, tube bending, pressing

Service Introduction

We offer hydraulic forming, tube bending, and stamping services, specializing in the precision processing of metal materials. Hydraulic forming technology is ideal for complex metal shaping needs, ensuring high precision and stability. Tube bending ensures accurate tube bending angles, maintaining precision in every detail. Stamping technology enables efficient, high-volume production of metal components, suitable for various metal materials, and performs particularly well in large-scale production settings.

These processing technologies support large-scale production, efficiently handling diverse demands while ensuring product stability and high precision, all while offering comprehensive cost control to help customers reduce production costs.

Hydraulic forming technology shapes metals precisely under high pressure, ensuring uniformity and strength in each formed part. Tube bending technology is highly flexible, able to handle various tube materials while ensuring accurate bends. Stamping technology significantly boosts production efficiency, making it ideal for high-volume production and lowering unit costs.

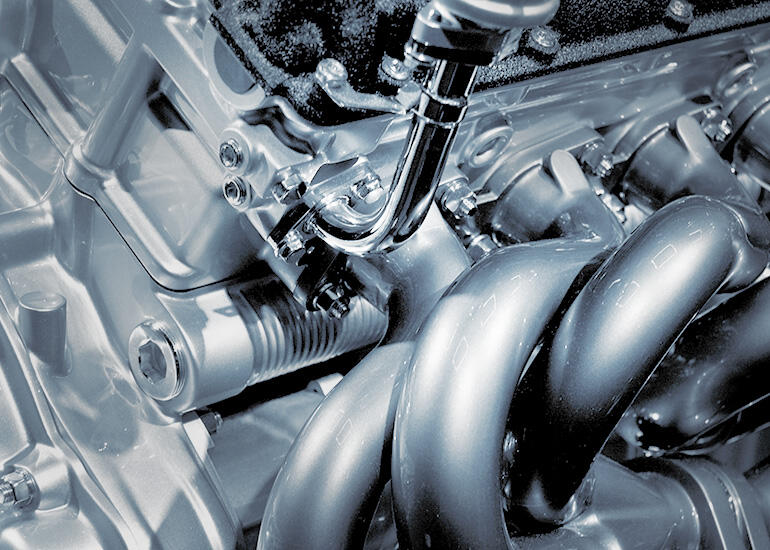

Our hydraulic forming, tube bending, and stamping technologies are widely applied in the bicycle industry, particularly in the precise manufacturing of bicycle frames, handlebars, and other metal components. Hydraulic forming handles aluminum alloys and steel, creating complexly shaped frames that balance strength and lightness. Tube bending technology ensures precise tube bending, improving the stability and comfort of bicycle frames. Stamping technology is ideal for large-scale production of frames and handlebars, maintaining high precision, improving production efficiency, and reducing costs to meet the market's demand for lightweight and durable products.